Single-Use Pressure Sensors

Single-Use Pressure Sensors for Bioprocessing | Pendotech

Monitor Pressure in Your Bioprocess with Confidence

Pendotech’s Single-Use Pressure Sensors™ for bioprocessing provide accurate and cost-effective pressure measurement for both gases and liquids in biopharmaceutical processes. Whether you need to track static pressure in a filtration system or dynamic pressure in a disposable bioreactor, these sensors are designed to adapt to your workflow.

Why Choose Single-Use Pressure Sensors?

- Accurate and Reliable: Equipped with MEMS-HAP™ high-accuracy pressure chips for consistent readings across your process.

- Cost-Effective: Affordable enough for disposable pressure measurement for biopharma applications, yet robust for repeated cleaning.

- Versatile Applications: Perfect for filtration, chromatography, gas monitoring, disposable bioreactors, and filling operations.

- Sanitization Ready: Made from caustic-resistant polysulfone, compatible with common cleaning processes.

Integration & Compatibility

Pendotech sensors are compatible with multiple monitoring systems:

- PressureMAT™ System – Monitor and transmit pressure data in real-time.

- Pendotech Process Control Systems (PCS) – For automated multi-sensor setups.

- Third-Party Monitors – Pre-qualified integration with selected systems.

Rated for use up to 75 psi, these sensors provide flexibility and reliability for small- to medium-scale biopharmaceutical processes.

Applications in Bioprocessing

Pendotech sensors are ideal for inline pressure monitoring for scenarios such as:

- Filtration & chromatography systems

- Gas monitoring in disposable bioreactors

- Filling operations and small-scale production workflows

- Other applications requiring precise pressure measurement in biopharmaceutical processes

Pendotech pressure sensors help you:

- Monitor pressure in single-use bioprocessing without stainless transducers

- Maintain tight control during filtration, TFF, or bioreactor operations

- Reduce hold-up volume and protect product yield

- Integrate seamlessly with existing monitoring or control systems

- Simplify QA and compliance with fully tested, USP Class VI materials

Additional Products

Pendotech Single-Use Pressure Sensors are designed for teams running small- to mid-scale bioprocessing workflows who need accurate, low-hold-up, single-use pressure monitoring that integrates seamlessly with a PressureMAT™ System (monitor/transmitter), Pendotech Process Control System (PCS), or third-party pumps and monitors.

When to Choose a Pendotech Pressure Sensor

Best for scenarios like:

- When you need pressure monitoring during depth filtration or TFF/crossflow filtration

- When a single-use, sterilizable sensor is required

- When your tubing runs from 1/8 inch to 1.5 inch ID

- When you need ‐7 to 75 psi measurement accuracy in flexible tubing

- When minimizing hold-up volume is critical to yield

- When you must integrate with existing pumps, controllers, or PAT systems

How the Sensors Integrate into Your Process

Pendotech pressure sensors can connect to:

- PressureMAT™ System

For teams needing a compact monitor/transmitter with alarms.

- Pendotech Process Control System (PCS)

For multi-sensor setups or automated control.

- Third-Party Pumps & Monitors

Pre-qualified for easy drop-in integration.

Outputs:

Data can be sent to a PC or any external monitoring device (PC output comes from PMAT or PCS, not directly from the sensors).

Common use cases

- Multi-stage depth filtration – consistent pressure tracking across filter trains

- TFF / crossflow filtration – maintain TMP without traditional stainless transducers

- Bioreactor pressure monitoring – sterile, single-use compatible

- General upstream & downstream bioprocessing

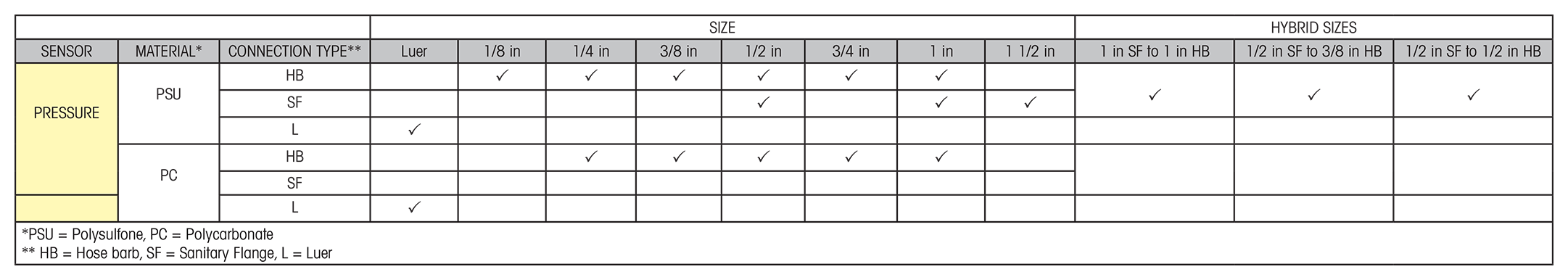

Compatibility & Operating Ranges

- Pressure range: –7 to 75 psi

- Tubing sizes: 1/8 inch to 1.5 inch ID (luer option available)

- Sterilization: Gamma & x-ray irradiation compatible

- Documentation: Validation guide available

Design & Performance Features

- Unobstructed flow path & no dead legs provides dramatically reduced hold-up volume versus stainless steel transducers or gauges

- Integral 12-inch cable connects to reusable monitor/ transmitter/alarm cable via molded connector

- Suitable for tubing from 1/8 inch to 1.5-inch inner diameter (luer size available separately) or a sanitary flange

Design & Performance Features

Minimal Hold-Up Volume

Unobstructed flow path + no dead legs → reduces product loss during small-scale runs.

Integrated 12-inch Cable

Connect directly to a reusable monitor/transmitter/alarm cable.

Flexible Connection Types

- Direct tubing (1/8–1.5 inch)

- Luer (ordered separately)

- Sanitary flange

Materials, QA, and Compliance

Construction

- Polycarbonate or caustic-resistant polysulfone

- All materials meet USP Class VI

Manufacturing & QA

- Built in an ISO 9001–certified clean room

- Each sensor tested – rejected if out of specification

- No calibration required

Documentation

- Certificate of Conformanceincluded

- Optional NIST calibration certificate

Hose Barb Design: Preventing Leaks

This design reduces the chance of tubing leaks by eliminating a mold parting line.

Why it matters:

- Single barb shaft lets the hose relax behind the barb for a secure drawstring effect

- Anti-rotation device holds tubing in place during twisting or repositioning

For higher-pressure needs:

- BarbLock

- Oetiker clamp

- Both provide 360° radial compression sealing

Sensors for Smaller Scale Processes (Luer Models)

Ideal for applications like:

- Low-flow in-line monitoring (1/8 inch)

- Dead-end measurements using included cap

- Adaptation to 1/4- or 3/8-inch barb fittings with luer ports

Sterility – Polycarbonate version ships sterile for aseptic setups.

Data & Technical Tables

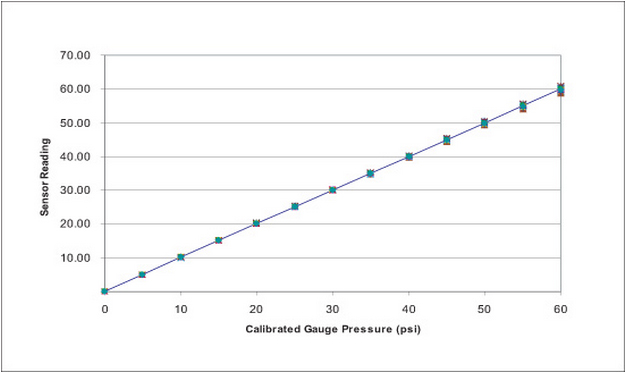

* Data from 100 random sensors manufactured with the PendoTECH High Accuracy Pressure chips (MEMS-HAP chips) and measured with the Pendotech Process Control System.

BarbLock® is a registered trademark of Saint-Gobain Performance Plastics Corporation all rights reserved.

Adaptor Cables for Third Party Monitors

- PDKT-650-298SC – Reusable shielded 6 ft connector cable w/ phone jack for Scilog pumps

- PDKT-650-298MG – Reusable shielded 6 ft connector cable w/phone jack for Midgee monitor

- PDKT-650-298MN – Reusable shielded 6 ft connector cable w/ phone jack for Pall Minim

Fittings

- PDKT-103-03 – 1/4 inch x 1/4 inch polycarbonate straight connector with luer port

- PDKT-104-03 – 3/8 inch x 3/8 inch polycarbonate straight connector with luer port

- PDKT-105-03 – 1/ 2inch x 1/2 inch polycarbonate straight connector with luer port

- PDKT-V3PS-000 – Luer polysulfone 3-way stopcock

- PDKT-650-298 – Reusable shielded connector 12 ft cable for sensor w/ colored leads

- PDKT-650-298BH – Bulkhead connector for panel mount connection of Pendotech Pressure & Conductivity Sensors

- PMAT-EXT-12F – Pressure senor extension cable (12ft)

- PDKT-650-298CVR – Pressure sensor cable dust cover/zero simulator for PressureMAT

Data Sheets

- Single-Use Pressure Sensor Data Sheet

- Single-Use Pressure Sensors for Use in Flexible BioProcess Containers Data Sheet

- Pendotech cable adaptor for Single-Use Pressure Sensor – PDKT-650-298

Technical Notes

Product Guides

Technical Instructions

- Panel mount connection of Pendotech Pressure & Conductivity Sensors- PDKT-650-298BH

- Technical Note: Pressure Sensor Materials

- Pendotech Single-Use Pressure Sensors: Calibration, Accuracy, and Implementation

- Pendotech Sensor Chemical Compatibility

- Technical Note: Pendotech Sensors and Industry 4.0: Integrating a Pendotech Single Use Sensor System with a Digital Highway

Application Notes

- Application Note: Versatile Sensor Solutions

- Application Note: Peptide Bioprocessing Purification Using Advanced Flow and Pressure Sensors

- Application Note: Pendotech Single-Use Pressure Sensors™: For Single Use and Glass Bioreactor Monitoring and Control

- Application Note: Preliminary X-Ray Irradiation Evaluation

- Application Note: Autoclave

- Application Note: Short Term NaOH Compatibility

- Enhancing Recombinant Vaccine Production with Single-use Sensors Application Note

- Greater Depth Filtration Performance Through Turbidity and Pressure Monitoring Application Note

- Enhancing Biotherapeutics Safety Application Note

- Improve Perfusion Cell Culture with Controlled Pressure and Flow Rate Application Note

Articles

- “Single-Use Pressure Sensors for Continuous Processing and Leak Testing” – Dennis Annarelli, PhD, Mark Marrano, Josh Huang, and Jim Furey- Genetic Engineering News, (Sept 2018)

- “Single-Use Noninvasive Sensing Technology” – Jim Furey – Genetic Engineering News, (July 2009)

- “Using In-Line Disposable Pressure Sensors to Evaluate Depth Filter Performance” – Lee R. Bink and Jim Furey – BioProcess International 8(2), (February 2010)

- “Measuring Pressure at Very Low Levels with High Accuracy in Single-Use Systems” – Dennis C. Annarelli, Jim Furey, Benjamin Less, and Joshua Huang – BioProcess International 13(3)s, (March 2015)

* Please contact your local Pendotech representative for a quote.

© Copyright 2026 Mettler-Toledo Pendotech

© Copyright 2026 Mettler-Toledo Pendotech